When it comes to running a warehouse efficiently, one crucial factor that is often overlooked is the lighting. The right lighting not only enhances visibility but also contributes to the overall productivity and safety of the facility. In this comprehensive guide, we will explore the key considerations for selecting the perfect lighting solutions for your warehouse. From understanding different lighting types to evaluating energy efficiency and maintenance, we’ve got you covered. Let’s illuminate the path to a brighter and more optimized warehouse environment.

Importance of Proper Warehouse Lighting

Before diving into the specifics of choosing warehouse lighting, let’s first understand why it is so important. Proper lighting in a warehouse setting improves visibility, reduces the risk of accidents, enhances employee productivity, and promotes overall operational efficiency. It creates a safe and comfortable working environment, allowing workers to perform their tasks with precision and accuracy.

Assessing Warehouse Lighting Needs

The first step in selecting the perfect lighting solutions for your warehouse is to assess your specific needs. Take into consideration factors such as the size and layout of the warehouse, the nature of the work being conducted, and any specific lighting requirements for certain areas or tasks. By understanding your lighting needs, you can make informed decisions throughout the selection process.

Types of Warehouse Lighting

There are several types of lighting commonly used in warehouses. Let’s explore each type and its unique characteristics:

a. High-Intensity Discharge (HID) Lighting

HID lighting includes metal halide and high-pressure sodium lamps. These lights produce a bright and intense illumination, making them suitable for large warehouses with high ceilings. They offer good color rendering and have a long lifespan, but they require a warm-up time and can be less energy-efficient compared to newer technologies.

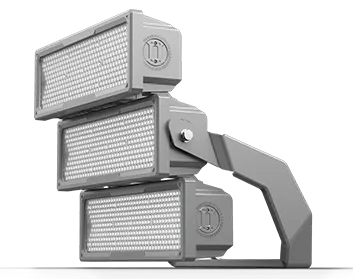

b. LED Lighting

LED lighting has gained immense popularity in recent years due to its energy efficiency, longevity, and versatility. LEDs produce bright and focused light, making them ideal for warehouse settings. They have instant startup, excellent color rendering, and are available in various color temperatures. Although they may have a higher upfront cost, LEDs offer significant energy savings and lower maintenance requirements in the long run.

c. Fluorescent Lighting

Fluorescent lighting is a cost-effective option commonly used in warehouses. It provides even and diffused light, making it suitable for areas where tasks require consistent illumination. Fluorescent lights are available in different configurations, including T5 and T8 tubes. They are relatively energy-efficient and have a moderate lifespan.

Evaluating Energy Efficiency

Energy efficiency is a critical consideration when selecting warehouse lighting. Not only does it contribute to cost savings, but it also aligns with sustainability goals. Look for lighting solutions that are ENERGY STAR certified or have high efficacy ratings. Implementing lighting controls such as motion sensors and dimmers can further optimize energy usage by automatically adjusting light levels based on occupancy.

Lighting Maintenance and Durability

Warehouse environments can be demanding, so it’s essential to choose lighting solutions that are durable and require minimal maintenance. Opt for fixtures with sturdy construction and robust materials that can withstand harsh conditions. Additionally, consider the ease of maintenance, such as access for bulb replacements or cleaning. Investing in lighting systems with long lifespans and warranties can also save you time and money in the long term.

Safety Considerations

Safety should be a top priority when selecting warehouse lighting solutions. Ensure that the chosen lighting meets relevant safety standards and regulations. Adequate lighting levels should be maintained in high-risk areas such as loading docks, stairways, and walkways to prevent accidents. Emergency lighting systems should also be installed to provide illumination during power outages or emergencies.

Maximizing Natural Light

Incorporating natural light into your warehouse design can provide numerous benefits. It not only reduces reliance on artificial lighting during daylight hours but also creates a more pleasant and visually appealing work environment. Consider incorporating skylights, windows, or translucent panels to harness natural light. However, ensure that these elements do not create glare or compromise insulation.

The Role of Lighting Design Professionals

For complex warehouse lighting projects, it is advisable to consult lighting design professionals. These experts can conduct detailed lighting assessments, provide customized solutions, and optimize lighting layouts for maximum efficiency. Their expertise can help you achieve the perfect balance between lighting performance, energy efficiency, and cost-effectiveness.

Conclusion

Selecting the perfect lighting solutions for your warehouse is a critical decision that can significantly impact productivity, safety, and overall operational efficiency. By understanding the importance of proper lighting, assessing your specific needs, exploring different lighting types, evaluating energy efficiency, considering maintenance and safety, and maximizing natural light, you can make informed choices that enhance your warehouse environment. Remember, consulting lighting design professionals can provide valuable insights and ensure optimal results. Illuminate your warehouse with the right lighting, and watch your operations shine.